Monitor Nitrogen Gas Use to Keep Workers Breathing Easy

I can’t breathe. Where am I? I am so confused. Why am I here? I can see the escape ladder but can’t seem to move my legs and arms to climb it. Standing in that dark space with no way to get out, panic sets in, still no air, everything goes silent.

Nitrogen gas is used in a variety of operations to replace oxygen and prevent the effects of oxidization; however, it can deplete the oxygen in the workplace environment and expose workers to significant hazards. According to the Bureau of Labor Statistics, from 2016 to 2020, 210 American workers lost their lives due to oxygen deficiency. Twenty-eight of those workers died specifically because of oxygen depletion.

Nitrogen is a colorless, odorless, tasteless gas that is the most plentiful element in Earth’s atmosphere. It is part of what we breathe. The atmosphere contains approximately 78% nitrogen, 21% oxygen, and 1% other gases. But when oxygen levels drop below 21%, the effects can be devastating and even deadly. Brain cells can begin to die within 5 minutes of the oxygen supply being eliminated.

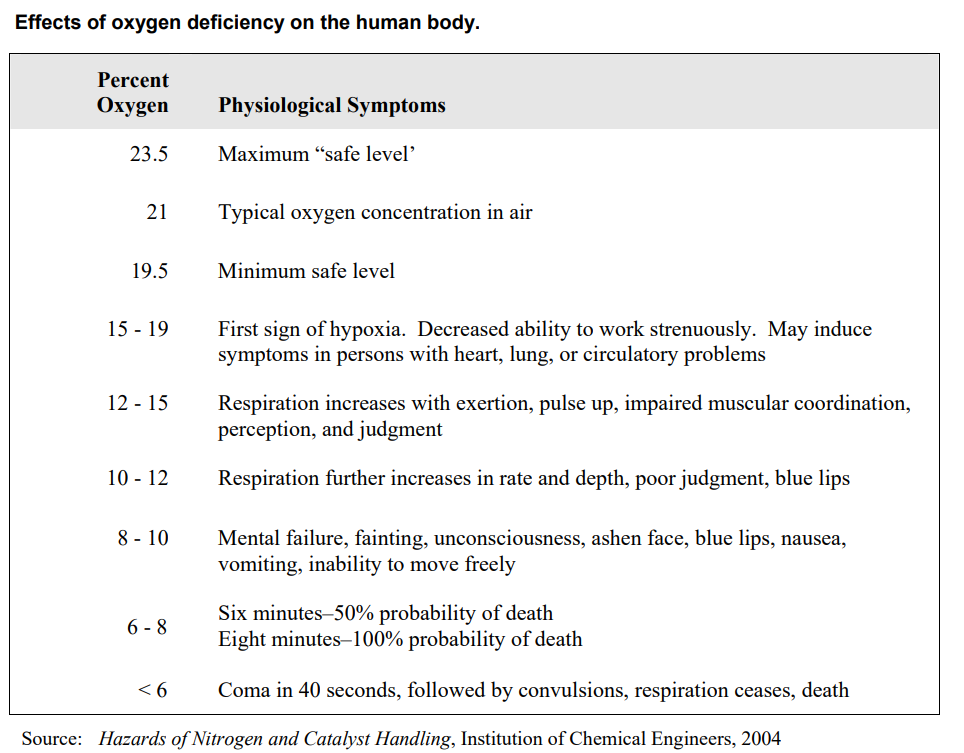

The table below describes the effects of oxygen deprivation in atmospheres with less than 19.5% oxygen. Poor judgment, confusion, and motor skill impairment can set in at 12-15% oxygen.

Oxygen deficiency can be caused by many things and is not always the result of nitrogen, but this gas is used for a variety of reasons and might even be in use at your workplace. Due to its unreactive properties, it is used to create an inert, less combustible atmosphere or it can dilute other gases to prevent spoilage and corrosion. It is common to see nitrogen used in the automotive industry to inflate tires, metal work to prevent corrosion, food and cosmetic industries to preserve products, and petroleum industry to purge vessels to prevent combustion. Some fire suppression systems use nitrogen, and laboratory operations use the gas to concentrate samples. It can even be used to produce medical marijuana and put bubbles in your beer.

Employers and workers need to know if nitrogen is utilized during operations and identify the associated hazards. Adequate planning and procedures are required to ensure effective oxygen monitoring and maintain adequate oxygen levels. Training is important for workers to identify and respond to conditions that can lead to nitrogen asphyxiation. OSHA has compliance guide to classify chemical hazards including nitrogen – a simple asphyxiant.

Typically, nitrogen is used inside an enclosed environment such as a vessel or tank which can create dangerously low oxygen levels. To prevent tragedies, review the OSHA requirements for Permit Required Confined Space Entry at 29 CFR 1910.146, and ensure a written program and entry permit are utilized if entry near or in a Permit Required Confined Space will be necessary.

The Chemical Safety Board (CSB) has investigated incidents involving death from nitrogen asphyxiation, including a detailed case study and creation of a video relating to the Valero refinery disaster in Delaware City, DE, in which two contracted employees died. According to CSB’s case study, “an oxygen-depleted, hazardous atmosphere might be present outside the equipment near unsealed equipment openings.” This shows the importance of monitoring oxygen around the exterior of a space being purged with nitrogen as well as within the confined space. If nitrogen purge is used in any part of your business process, ensure consistent monitoring for oxygen levels, conduct training to inform employees of the hazards of nitrogen asphyxiation, and post warning signs and information in and around areas of nitrogen use.

Don’t let your employees fall silent due to a lack of understanding of the hazards of nitrogen asphyxiation.

MEMIC policy holders can access additional information on chemical safety and confined space on the MEMIC safety director or talk to your safety consultant.

For more information:

- US Chemical Safety Board - Hazards of Nitrogen Asphyxiation

- MEMIC Blogs: PELs,STELs,and Ceiling Limits and Confined Spaces in Construction (3 parts)