Increasing Engineering and Administrative Controls to Decrease Risk Exposure

One of the few pandemic silver-linings is that we have all had to think outside-the-box to accommodate COVID-19 protocols. We have done a great job adjusting but now that we have those protocols covered it’s time to refocus on the risks that our employees face every day.

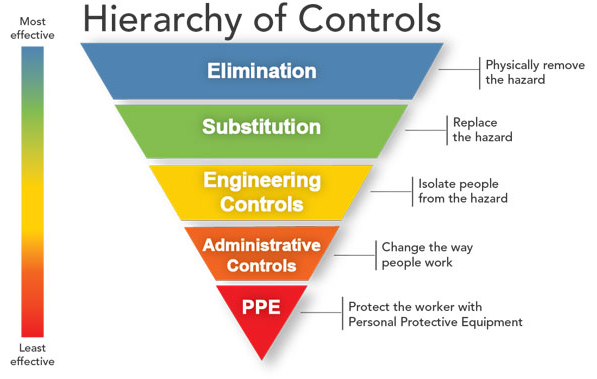

Following the Hierarchy of Safety Controls we should first eliminate and substitute as many risks as possible. Then it is time to determine how some simple engineering and administrative controls can help mitigate workplace injuries and comply with regulatory requirements. Let’s take a look at three common exposures and what controls can be implemented to protect workers.

Noise - Some design set-ups or adding new machines to an already noisy area can push the noise level over the permissible exposure limits and require a hearing conservation program. Not only does that expose workers to hazardous noise levels it is also expensive and time consuming to administer a hearing conservation program year after year. Isolating the machine, using acoustic tiles or blankets, or adding distance buffers around the machines could reduce the noise to safe levels. Often when you replace machinery with new versions, they will have a built-in noise control systems so consider this when it’s time to upgrade. Other administrative controls could include shift or job rotations to limit exposure times. PPE for noise protection is important, but it is the last choice in the hierarchy. Remember, occupational hearing loss is permanent, but it is also very preventable.

Heat - One exposure that you may not have addressed during the pandemic was heat stress potential. Considering all the new Personal Protective Equipment (PPE) that workers have been required to wear it might be a good idea to assess the stress that masks and face coverings can have on a worker, especially in the heat of the summer.

Heat - One exposure that you may not have addressed during the pandemic was heat stress potential. Considering all the new Personal Protective Equipment (PPE) that workers have been required to wear it might be a good idea to assess the stress that masks and face coverings can have on a worker, especially in the heat of the summer.

Most of us don’t have the equipment to do the heat stress calculation, but luckily OSHA and NIOSH have created a heat safety tool available for both Android and iPhone. This stress guide app allows for a quick and easy check of our work environment for heat stress. It also has a symptom and first aid list for managers and supervisors to use for guidance.

There are other affordable controls for heat stress such as cooling vests and towels available for $10 to $200. Some creative people have used fishing vests, filling the multiple pockets with frozen water bottles or ice packs to stay cool.

Of course, in New England using a fishing vest for the one or two days of really high temperature and humidity works well. But if you work in a much hotter part of the country make sure you go with cooling vests made for this purpose. Shop around for a vest that suits your needs as they do differ in the temperature they will maintain and the length of time they will provide effective cooling.

work in a much hotter part of the country make sure you go with cooling vests made for this purpose. Shop around for a vest that suits your needs as they do differ in the temperature they will maintain and the length of time they will provide effective cooling.

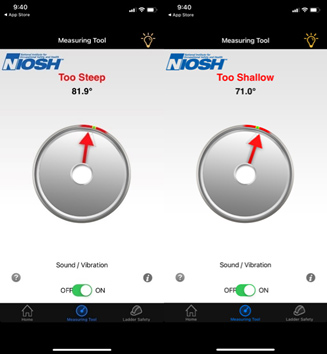

Falls from Ladders - Falls represent one of the most common causes of injury and falling from ladders results in over 164,000 emergency room visits per year. Sometimes the best control to reduce these falls is ensuring the proper equipment is used for the job. Most workplaces have a ladder or two laying around for functions above floor level; however, they might not be the right ladder for the task. NIOSH offers a free Ladder Safety App that assists workers in choosing the proper ladder and even monitors the ladder angle for stability.

It also provides a variety of questions to help choose the proper ladder for the job. Best practices would dictate choosing a ladder with a rating of 1A with a 300-pound load limit. This would, in most cases, ensure compliance with this OSHA standard: 1910.23(c)(3)

It also provides a variety of questions to help choose the proper ladder for the job. Best practices would dictate choosing a ladder with a rating of 1A with a 300-pound load limit. This would, in most cases, ensure compliance with this OSHA standard: 1910.23(c)(3)

The employer must ensure: Ladders are not loaded beyond the maximum intended load; Note to paragraph (c)(3): The maximum intended load, as defined in § 1910.21(b), includes the total load (weight and force) of the employee and all tools, equipment, and materials being carried.

Engineering and administrative controls are key elements to any safety program. Putting the right controls in place and ensuring compliance from every worker is critical. This is especially true of administrative controls as they depend upon the worker to follow their training and use the controls as intended. This is why engineering controls are more effective and found higher on the hierarchy.

For additional information on these topics, check out our previous posts Ladder Safety, Hearing Conservation for Hearing Conversation, and Don’t Hold the Ice: Crushed Ice for Control of Heat Stress.