The Science of Safety in the 21st Century

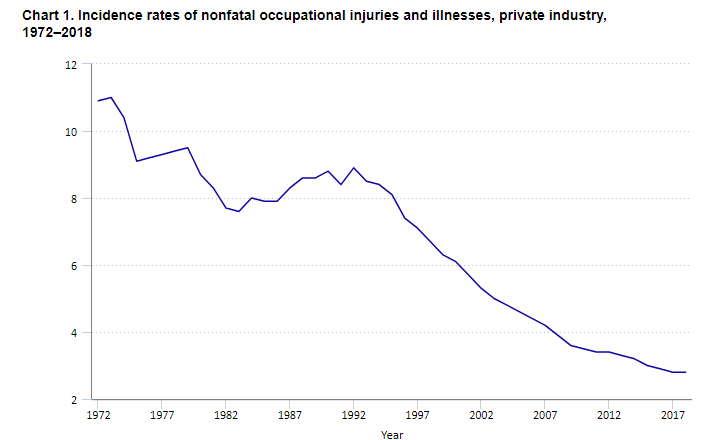

2020 marked the 50th anniversary of the Occupational Safety and Health (OSH) Act of 1970. The law was intended to ensure “so far as possible every working man and woman in the nation safety and healthful working conditions and to preserve our human resources.” As can be seen in this chart created by the U.S. Bureau of Labor Statistics, the country seems to have come a long way towards reducing workplace injuries over the decades. Now the challenge is to continue that downward trend as each injury represents significant human and economic toll. After all, there were 2,814,000 non-fatal recordable injuries and illnesses in private industry in 2019. Technology and advanced research may provide additional innovative solutions for further limiting workplace injuries.

Source: U.S. Bureau of Labor Statistics

Technology has definitely advanced over the years and some jobs are “safer” as typical risks have been reduced, or even eliminated. A significant amount of manual material handling has been replaced by machines or automation. Mechanical logging crews have largely replaced the hand crews using chainsaws. However, as processes have evolved so have the injury risks associated with those activities. Lack of “work hardening” among laborers might mean more ergonomic injuries, and large machines moving through the woods present their own set of safety, as well as operational, challenges.

Sometimes we use safety techniques designed in the 20th century to address risks created in the 21st century. Some of these controls continue to be effective, others do not. This is where research comes in. To effectively address all risks faced by employees and employers, we need to continue advancing the science of safety. More recently developed controls that have proven effective include light curtains in machine guarding applications, CNC machining tools, and advanced driver safety features such as adaptive cruise control or automatic emergency braking. Wearable technology is another innovation that has huge potential. Safety science needs research that is unbiased towards a particular product or process so advancements in all safety areas can continue.

Some of that research may include advanced analytics, including “predictive” analytics that may allow us to reduce risk even further. Computer technology is almost certainly part of the answer as we look towards advancements that will further reduce the odds of workplace injury. But we can never underestimate the need for more human centered training and education using the most current science surrounding adult learning, psychology, and other social sciences.

The MEMIC Group was founded on our relentless commitment to workforce safety. As a workers’ compensation company focused on safety, we strive to provide the best safety consulting, training, tools, and knowledge to all our policyholders to assist them in their injury prevention efforts. Our philosophy has long been that an injury should not be a by-product of work. Neither employees nor employers expect an injury to occur on any given day. Yet, injuries do occur and sometimes with catastrophic results.

The MEMIC Safety Research Center has been created for exactly this reason. Our hope is that the research undertaken by the Center will help advance the knowledge of safety by identifying and producing new techniques, devices, and training, thereby benefiting employers and their workforce.

February 10th marked the Center inauguration, and it will serve as a bridge between our policyholder and business partners, academia, and state entities to transform ideas into real-life solutions. In our first year, the Safety Research Center will make available up to $30,000 in grants for safety research to academic institutions.

As we often say, “safety never takes a holiday.” Not only should it be on the job at all times, safety must also evolve, include the latest innovations, adapt to workers of all generations, and provide solutions to both today’s and tomorrow’s risks. MEMIC policyholders have our commitment to workforce safety, and our Safety Research Center will help keep safety relevant. But we also need the help of each policyholder by keeping safety in the forefront. Be willing to embrace new technology that will make operations safer. Foster a positive culture that supports safety at all levels, and do all you can to operate productively while ensuring everyone goes home as healthy as they arrived.