Job Safety Analysis Made Easy

November 01, 2016

General, Safety Programs

A job safety analysis (JSA) is a process that allows us to effectively break down a job into specific steps to identify potential hazards and to recommend the safest way to complete the job, this is done by observing a worker actually perform the job and having a group of experienced workers and supervisors complete the analysis through discussion.

What are the JSA steps?

- Identify a single job to be analyzed.

- Breakdown the task into individual steps.

- Identify the hazard(s) associated with each task.

- Identify methods to eliminate and/or control the hazard(s).

- Sign and date the JSA.

How can I ensure that the JSA process is a success?

- Keep the process simple and try not to overthink it.

- ALWAYS include your workers and supervisors in the process. They will appreciate being part of the process and it will give everyone a sense of ownership.

- Follow up if/when controls are implemented to ensure that they have effectively eliminated/reduced the identified hazard(s).

- Reach out to your MEMIC loss control representative for assistance in getting the process started.

What are the benefits of a JSA program?

- Identifying potential hazards and controls for specific jobs greatly reduces the likelihood of injury!

- The process of conducting a JSA gets people thinking a little bit differently about the jobs they perform and all of the potential hazards that may have been overlooked.

- Completed JSAs are a great resource for new employee safety training (orientation) as well as frequent refresher training.

- JSAs can help improve efficiency by identifying and eliminating non-value added steps.

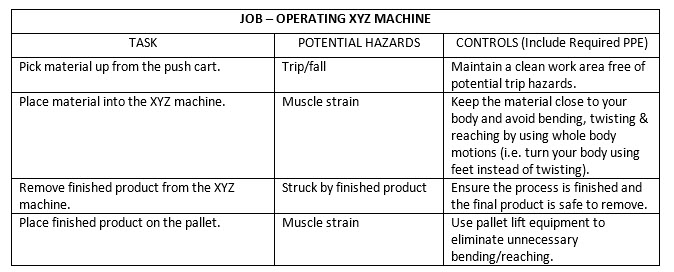

What does a completed JSA look like?

- For this example, we will only list one hazard for each task. Please note that it is common for each task to have more than one potential hazard.

For more information regarding JSAs check out the resources available in the OSHA publication entitled Job Hazard Analysis. MEMIC customers can find more resources within the MEMIC Safety Director.