Compressed Gas Cylinder Handling

Compressed gas cylinders are used across many different industries ranging from restaurants, medical, and in industrial settings. While different gases have different properties, they have similar hazards regarding identification and handling.

Identification: Compressed gas cylinders should only be identified by their labels and NOT by the color of the cylinder. In 2012, the OSHA Hazard Communication Standard (HCS) was updated to adopt the U.N. Globally Harmonized System (GHS) for classification and labeling of chemicals. GHS compliant labels will have one or two pictograms indicating the type of hazards the type of gas present. The most common type of hazards are flammable, inert, and oxidizer gases. Flammable gases and oxidizers must be separated by 20’ or a 5’ high ½ hour burn wall. All labels will have the hazard pictogram in the center of the label with the gas type written to the left.

Cylinder Handling: When handling cylinders there are several good practices to implement to prevent injuries. When moving a compressed gas cylinder, always use a suitable hand cart and secure the cylinder to the cart prior to movement. If a cylinder begins to slip out-of-control, do NOT try to catch it; this is a primary cause of injury. When a cylinder is properly capped, it is very unlikely that the valve will be sheared off during a fall. Another common injury occurs when employees try to lift a cylinder by the cap. Cylinder caps are not engineered to hold the weight of a cylinder. As the cylinder cap threads wear down it is possible for the cap to be pulled off leading to injury.

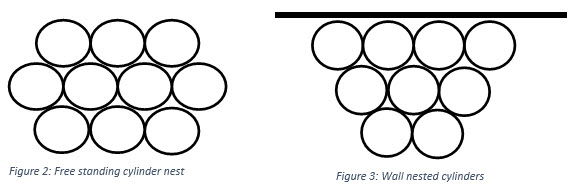

Cylinder Storage: All compressed gas cylinders in service or in storage should be secured by chain or strap to prevent falling or rolling. At gas suppliers’ facilities and distributors’ warehouses, the ‘nesting’ of cylinders is considered an equivalent safe manner of storage. Nesting compressed gas cylinders is defined as each cylinder having three points of contact with either a wall or other gas cylinders.

Examples of cylinder nesting:

As with all work places, it is important to have a clean environment when working with compressed gases. While common cylinders can weigh as little as 5lbs and as much as 200lbs, they all pose a hazard and should be treated with equal respect. Regardless of size, compressed gas cylinders contain 2,000psi – 2,200psi. When working with compressed gas cylinders remember to keep the areas clean, fix loose rugs and uneven flooring, and clean up water, oil, or other liquid spills. Certain types of gases also have specific hazards. If working with carbon dioxide, it is recommended that a CO2 alarm be installed due to the potential oxygen displacement. As always, if you have questions, the manufacturer of the compressed gas is listed on the label can be used a resource to learn more about the specific hazards of any compressed gas cylinder. More information can also be found at the Compressed Gas Association website.