Which Extension Cords to Use - Lightweight Cords can be Shocking

Employers and employees often don’t recognize the exposures associated with using light duty extension cords and cords not listed and labeled for commercial and industrial use. The Consumer Product Safety Commission estimates that the misuse of extension cords causes about 3,300 fires each year, killing about 50 people and injuring an additional 270 people.

Both OSHA’s general industry 1910.305(g)(2)(i) and construction 1926.405(a)(2)(ii)(J) standards require extension cords designed for hard or extra-hard usage. The National Electrical Code (NEC) has different designations for extension cords (Table 400.4). Hard-service cords are marked with letters such as S, SE, SO, ST; junior hard service cords are marked with letters such as SJ, SJE, SJO, SJT or SJTO. Other letters may be included after these that indicate the nature of the insulation or outer covering.

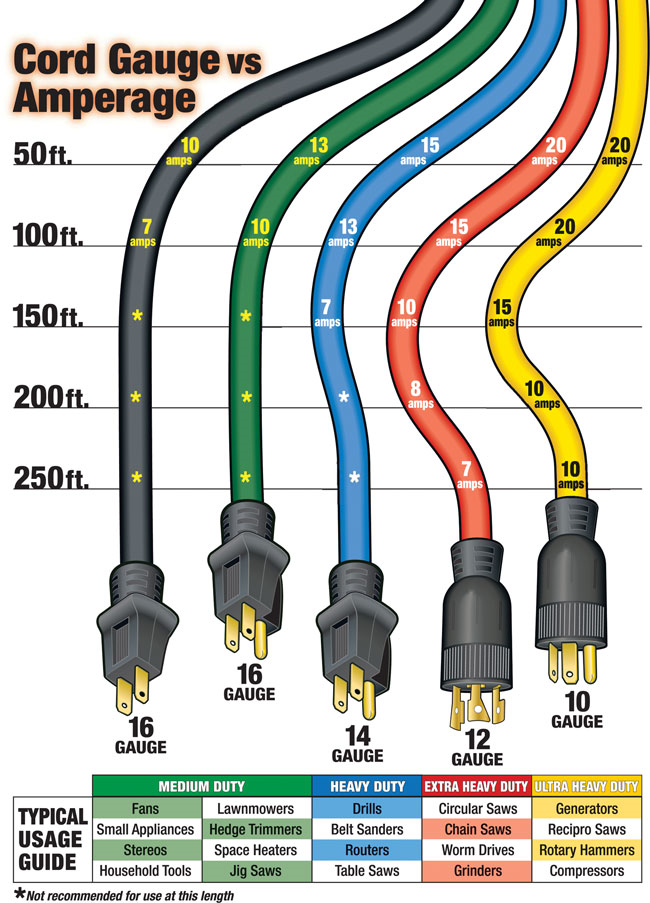

Often in an effort to save money, a light duty, or light gauge extension cord is purchased by the employer or brought to the workplace by employees. The wires inside an extension cord can have different thicknesses. Extension cords with thick copper wire can carry more electricity. Thickness of a wire is denoted as “gauge” or “AWG”, which stands for American Wire Gauge. Extension cords typically range anywhere from 18-gauge to 10-gauge, with 10- gauge having the most copper in the wire. Lower gauge wires allow more electrical current to flow through the extension cord.

A serious exposure exists when light duty indoor rated 18 and 16-gauge (zip and ribbon style) cords are used. This ribbon extension cord is used around homes to plug in such devices as lamps, clocks, and other low voltage and low amperage rated devices up to 7 amps. An under-the-desk space heater can use around 12.5 amps. The ribbon extension cord is only rated for 7 amps; however, anything more will result in the cord being overheated. A ribbon extension cord should never be used in commercial or industrial type settings.

When a safety compliance officer identifies these cords in the workplace the following OSHA regulation is often referenced because of the cord load rating. OSHA 29 CFR §1910.304(b)(2), Outlet devices: "Outlet devices shall have an ampere rating not less than the load to be served."

These lightweight cords present a variety of safety exposures:

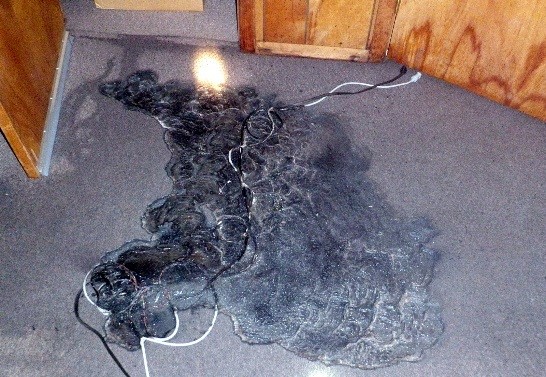

Fire Ignition Hazard: Light duty 18 or 16-gauge cords will not carry the amperage being provided by a typical 15 or 20-amp receptacle found in all home and business locations. A 15 amp circuit breaker won’t open and protect the circuit until the 15 amps is exceeded, but this could result in overheating and failure of the cord before the circuit breaker can trip.

An overheated wire can break down the insulation and expose the internal wires to combustible materials resulting in fires. Additionally, the longer the cord the more current is lost due to resistance. This can lead to cord damage and equipment overheating. The Consumer Product Safety Commission issued a safety alert about improper extension cord use.

Resistance Hazard: Lightweight extension cords generate resistance which produces heat. The smaller the wire gauge and longer the cord the more heat being generated in the wires. The higher the current the greater the resistance and heat. Lightweight cords, older cords, and heavily used extension cords can begin to break down. If a heavily used light duty cord is used for a power-hungry piece of equipment, the cord could get hot enough to degrade the protective insulation and start a fire.

Grounding Hazard: Light duty cords often do not contain three wires. Any time a two-wire extension cord is introduced in the workplace it creates a possible exposure when employees need three-wire power supplies. Often the ground pin is bypassed or removed from the tool’s plug.

The Electrical Safety Foundation International (ESFI) offers tips for staying safe from electric shock and electrical fires. MEMIC policyholders can learn more about electrical safety by accessing our Resource Library and the Safety Experts Podcast by clicking the Workplace Safety tab at MEMIC.com.